What is Procurement Category Management? (PCM)

Procurement category management is a means of organising product groups to meet shopper needs and to create greater purchasing efficiencies.

Procurement category management focuses on prioritising consumer needs and desires with every retail decision through the use of product categories. But the procurement aspect sharpens the focus on organisational spend in line with various business goals.

Category management is defined as a ‘strategic approach to procurement’. When done effectively it helps to guide essential decisions on business continuity and business support. This means ongoing profitability and success. Also, a healthier bottom line. Additionally, it works to build a strong position against key competitors.

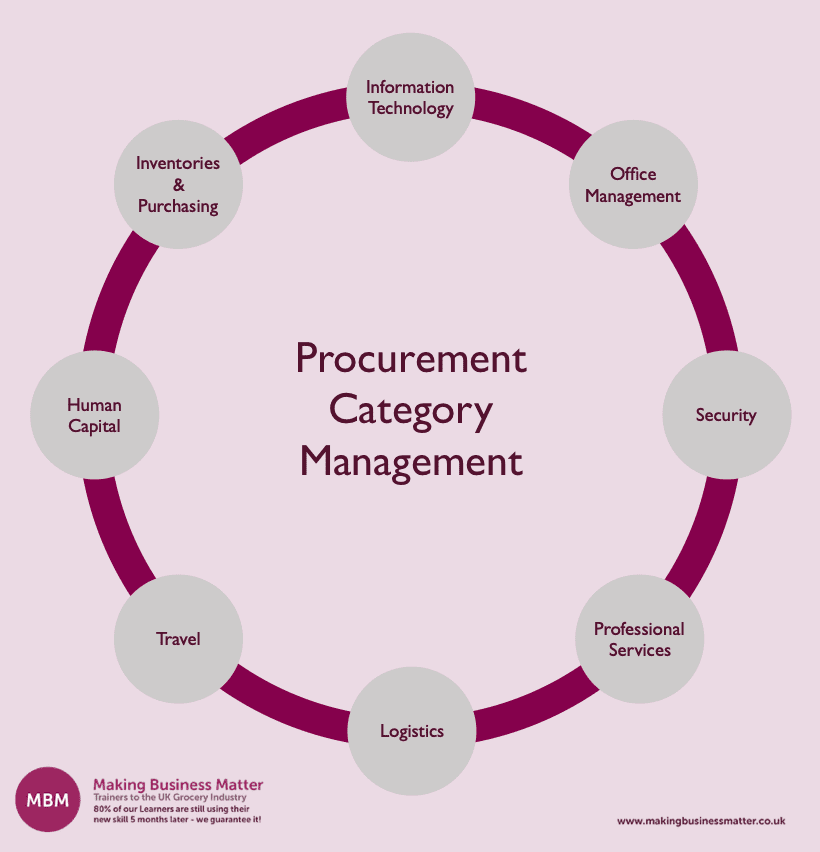

Procurement category management makes sure that businesses do not adopt unhealthy spending habits or exceed budgets. It also supports intelligent purchasing decisions for company goods and services. This includes wider areas, such as office management and security, as well as detailed decisions such as inventory purchasing.

How Does Procurement Category Management Work?

First, we should look at the purchasing element and purchasing activity with regards to meeting consumer needs. In this aspect, procurement category management covers some key areas.

Spend analysis will define how much budget is allocated to each category and sub-category. Influential factors might include the season (i.e. more budget allocated to gifts at Christmas). Current market trends and competitor activity are also key factors. The media may play a role in how much spend is allocated to product sub-categories. For example, if a particular item is garnering a lot of attention in print and social media.

Market intelligence and analysis should also be applied to make decisions, such as, which vendors to use. Those responsible for procurement category management will analyse organisational spend in comparison to market data, trends, supplier performance data and key KPIs. This works to identify any gaps in the strategy and potential areas for improvement. They will also adapt their pricing structure using informed analysis of the local and international market and consumer trends.

Procurement managers and those involved in procurement category management must be savvy when it comes to identifying opportunities for cost savings. They can use key insights to find and add value. In turn, this works to support better supplier risk management and a more fluid retail chain. It also improves cash flow and business strategy.

Identifying financial goals and applications in advance creates an environment conducive to holistic spending and strategic demand management. This facilitates long-term decision making for stronger supplier-retail relationships, new opportunities for negotiation and better compliance.

PCM from Left to Right

In recent times, the school of thought around procurement category management has shifted. It has moved from left to right. Procurement value-added services have gained greater momentum. A shift in sales structures has seen more emphasis placed on sales driven by consumer demand. This contrasts to the more traditional structure where production drives sales.

In practice, this means putting the consumer first. The retail and manufacturing strategies build upwards from their needs and wants.

This contrasts with the traditional format. Where the retailer built the strategy. In turn, telling consumers what they need and want. The latter will inevitably prove less effective.

The diagram below demonstrates this. We like to call it ‘production push’, where sales were driven by production. And ‘consumer pull’, where sales are driven by consumer insight:

Innovation in two main areas has propelled these latest developments. Firstly, the rise of the digital supply chain. Secondly, the move towards a culture of greater collaboration. Experts now use procurement category management to make better financial decisions. Moreover, it drives innovation across different supply chain categories.

PCM and Digitisation

Digital supply chain management is the new buzz-phrase in procurement category management. Those who understand how to harness its potential are making great strides.

More and more businesses are moving towards digitisation. This is changing the face of procurement. It helps organisations to save time, money and administration costs. It also allows for quicker, more effective and informed business decisions.

Digitisation allows managers to build and keep up a competitive stance in line with real-time market trends and data. They can create a powerful environment for more streamlined processes. This might include key elements such as Big Data, crowdsourcing and the Internet of Things. It also supports larger companies in building a fluid supply chain across borders and oceans. This means more efficient retailer and supplier communications using cutting-edge media.

Building a Collaborative Culture

Procurement category management has always been about building and maintaining successful relationships. These help to gain useful insights. But now, more than ever, there is a focus on collaboration. The rise of digital technology has supported this trend. This, with an increased overlap with the supplier management process. These developments benefit all parties in the retailer-supplier relationship.

Also known as ‘category group planning’, it allows those involved with procurement category management to deliver greater value. It creates a stronger, more aligned relationship with internal and external stakeholders. Continuous engagement and a value-oriented supply chain play a key role in this model. This environment allows retailers and suppliers to build effective long-term and holistic strategies for managing spend. The goal should always be ongoing value improvement.

Ultimately, this ongoing value improvement would result in higher inventory turnover and optimum stock levels. This would further increase customer satisfaction. Moreover, reduced transportation costs are also likely. When every party is aware of the key purchasing decisions, this facilitates near-instant strategic decision making for improved cash flow. Retailers should also be able to consistently meet consumer demand using an effective communication model. Procurement managers can then respond quickly to changing customer trends and habits to meet the best returns.